Keep production on track

Manufacturing doesn’t pause for Patch Tuesday. PDQ Connect helps you deploy software and updates fast, whether you’re supporting production lines, kiosks, or warehouse PCs — all without a VPN. From AutoCAD installs to urgent security patches, you can provision, patch, and troubleshoot devices across all your sites without ever setting foot on the factory floor.

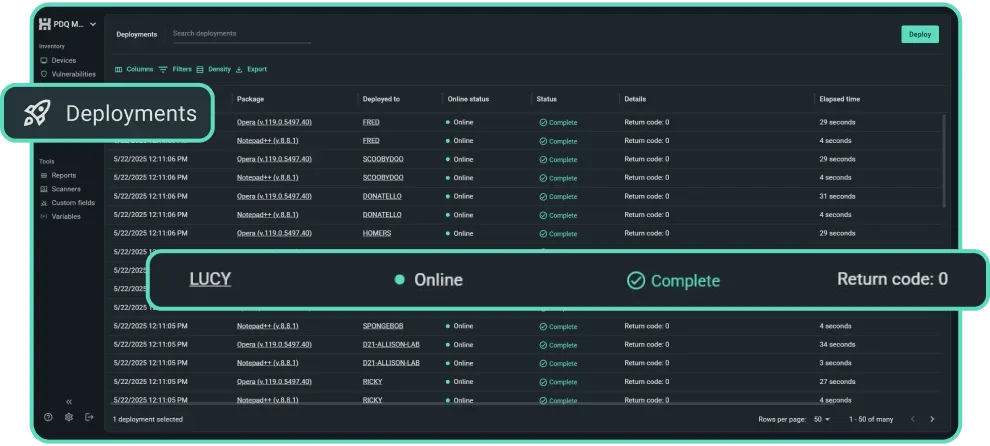

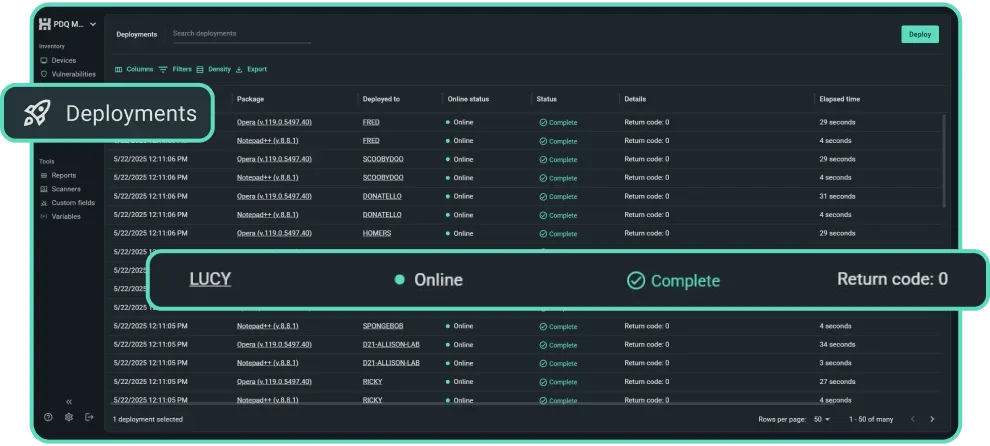

Deploy at scale

Rolling out devices across warehouses and production lines should speed up your operations, not slow them down. With PDQ Connect, you can deploy the apps, settings, and scripts you need from anywhere — without having to chase down devices.

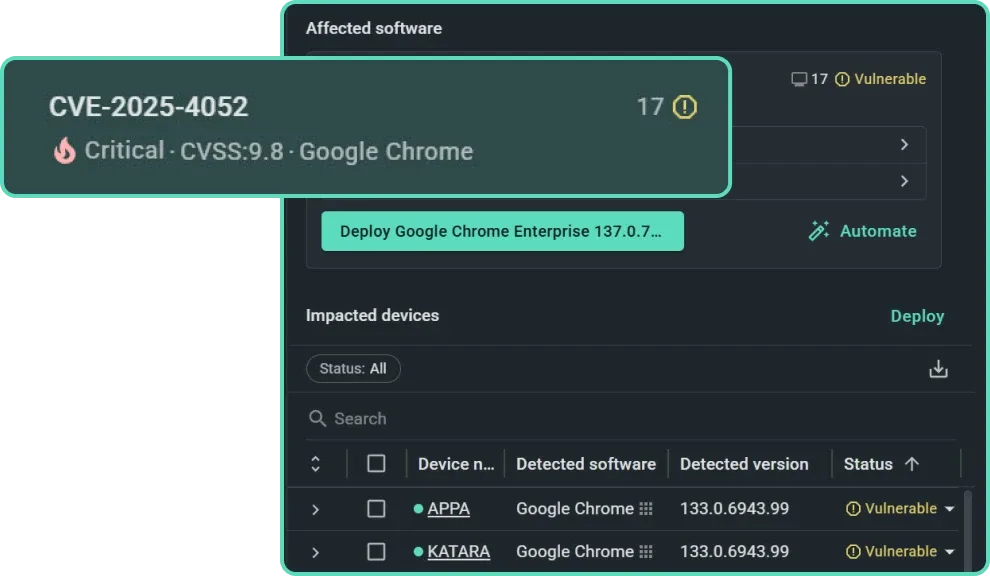

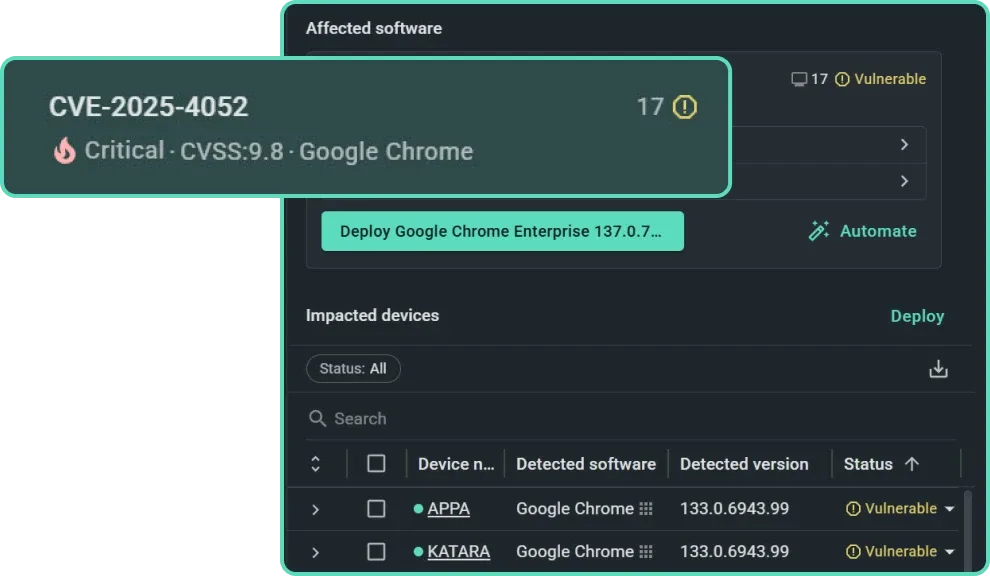

Patch in clicks, not hours

PDQ Connect helps you spot and patch vulnerabilities fast by grouping devices by risk factors (such as OS version, hardware type, or specific CVEs). Deploy fixes across warehouses and offices without waiting on VPNs or user check-ins.

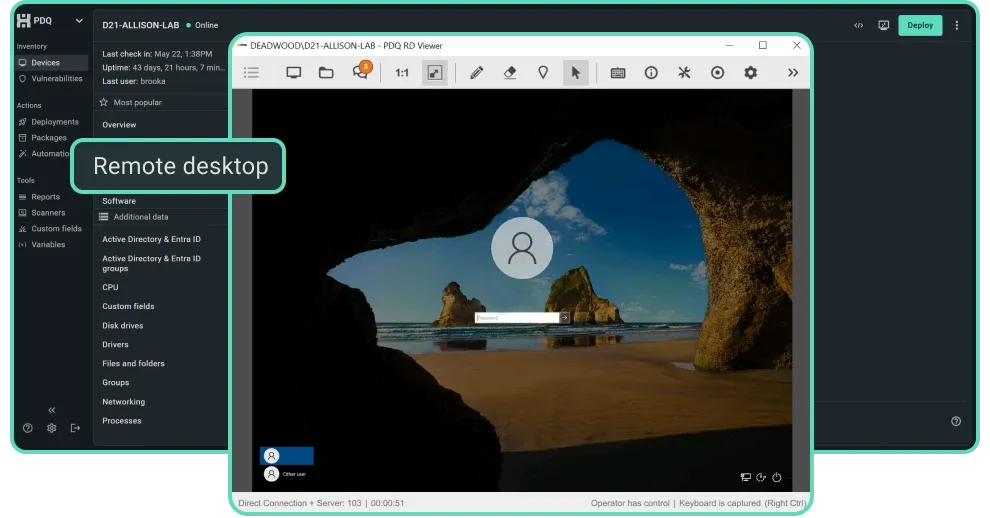

Support users in real time

PDQ Connect gives you detailed insights on installed apps, recent deployments, registry data, and more to help you troubleshoot without leaving your desk. And with remote desktop, it’s like you’re in the same room as your end users, even if you’re across the globe.

See why IT teams across the line count on PDQ Connect

We’re keeping our workstations patched and updated at a rate that wasn’t possible before PDQ Connect.

MARK WILLIAMS, IT TECHNICAL SOLUTIONS MANAGER

OSU CARLSON COLLEGE OF VETERINARY MEDICINE

For sysadmins, by sysadmins

Properly functioning devices can make the difference between meeting or missing production schedules. That’s why our team of former sysadmins has curated resources to quickly get you the help you need.

Experience it for yourself

FAQs

Can PDQ Connect manage factory floor devices that aren't always online?

Yes, PDQ Connect can manage factory floor devices that are intermittently online. Connect checks in with devices when they reconnect, allowing you to queue updates, run scripts, or monitor status without needing constant connectivity.

Does PDQ Connect work in air-gapped or semi-connected industrial environments?

PDQ Connect is not designed for fully air-gapped environments, as it requires internet access to communicate with devices. However, it works well in semi-connected setups where devices periodically come online, making it suitable for many industrial and factory floor use cases.

How can I ensure all Windows-based equipment receives security patches on time?

With PDQ Connect, you can automate Windows updates and patches. Use PDQ Connect to schedule recurring patch jobs, target specific device groups, and monitor patch status. For devices not always online, you can configure retry intervals or queue updates to install when they reconnect. This reduces manual oversight and patching delays.

Can PDQ Connect identify outdated firmware or driver versions?

PDQ Connect does not directly detect outdated firmware or driver versions. However, it collects detailed OS inventory data, allowing you to identify devices running outdated operating system versions. You can create dynamic groups based on this data to flag and prioritize systems that may need updates or further review.

How does PDQ Connect help reduce production downtime during updates?

PDQ Connect minimizes downtime by allowing you to schedule updates during off-hours, target specific device groups, and automate patching workflows. It queues updates for semi-connected devices and runs scripts without requiring a VPN, ensuring maintenance doesn’t interrupt production schedules.

Can I group and manage IT and OT (Operational Tech) endpoints separately?

Yes, PDQ Connect lets you create custom device groups using filters like OS version, device name, or last check-in time. This makes it easy to segment IT and OT endpoints, apply different policies, and manage each group based on its unique operational needs.

Does PDQ Connect support offline agent check-ins or caching?

PDQ Connect agents store tasks locally when devices are offline and execute them once reconnected. While it doesn’t cache updates like a WSUS server, it supports deferred check-ins and queued actions, making it effective for environments with intermittent connectivity.

What kind of deployment flexibility does PDQ Connect offer for shift-based environments?

PDQ Connect supports flexible scheduling, allowing you to deploy updates and scripts during specific time windows — ideal for avoiding disruption across shifts. You can target device groups by department or role, automate recurring tasks, and queue deployments for devices that come online outside regular hours.

How does PDQ Connect track asset information for compliance or auditing in manufacturing?

PDQ Connect automatically collects detailed asset data, including device names, OS versions, last check-in times, and installed software. You can filter, group, and export this inventory for audit trails or compliance reporting, which helps manufacturing teams maintain visibility across both IT and OT endpoints.

Is PDQ Connect lightweight enough for use on older or resource-limited industrial PCs?

Yes, PDQ Connect is designed to be lightweight, with minimal impact on system performance. Its agent runs silently in the background, making it suitable for older or resource-constrained industrial PCs commonly found on factory floors.